Styrene Copolymers: Types, Preparation, Properties and Applications

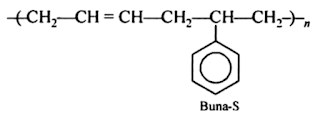

1. Butadiene-styrene Copolymer (SBR or Buna-S)

Buna-S or SBR is a copolymer of 1,3-butadiene and styrene which is prepared by copolymerization of 1,3-butadiene and styrene along with sodium. In Buna-S, Bu stands for butadiene, Na for sodium which is the polymerizing agent and S stands for styrene.

It is tough and is a good substitute for natural rubber. It possesses high abrasion resistance, high load-bearing capacity and is used for the manufacture of automobile tires.

Preparation of Buna-S

Styrene-butadiene rubber (SBR) or Buna-S can be prepared by copolymerization of a mixture of 1,3-butadiene and styrene in the ratio of 3:1 in the presence of sodium.

Properties of Buna-S

1. Buna-S has high abrasion resistance, high bearing capacity, and resilience.

2. Buna-S is very tough and is a good substitute for natural rubber

3. Buna-S swells in organic solvents up to a limited extent.

4. Buna-S gets oxidized in the presence of traces of ozone.

Applications of Buna-S

1. Buna-S is used for making floor tiles, footwear components, cable insulation, etc.

2. Buna-S is also used as a binder in the lithium-ion battery.

3. Buna-S is used as a part of cement-based waterproofing systems as it aids bond strength, reduces the potential shrinkage.

4. Latex Buna-S is widely used in the coated paper as it is the cheapest resin to bind pigmented coatings.

2. Styrene-maleic anhydride Copolymer (SMA)

Styrene-maleic anhydride (SMA) is a synthetic copolymer that undergoes copolymerization with styrene in a highly symmetrical manner to form styrene-maleic anhydride.

Preparation of SMA

Properties of SMA

1. SMA is a crystal clear and amorphous thermoplastic in nature.

2. SMA offers high heat and chemical resistance, high glass, and high melt velocity.

3. SMA is soluble in alkaline solutions and polar organic solvents.

4. SMA is also known for high functionality and reactivity.

Applications of SMA

1. SMA is used in the automobile industry for the manufacturing of car instrument panels and consoles.

2. SMA's surface provides excellent adhesion to polyurethane (PUR) foam which is used in padded instrument panels.

3. SMA (ester) resins are added in solvent-based coatings, adhesives, overprint varnishes, printing inks, etc because they act as dispersing and emulsifying agents.

3. Styrene-acrylonitrile Copolymer (SAN)

Styrene-acrylonitrile (SAN) is a copolymer plastic that is produced by copolymerization of styrene and acrylonitrile.

Preparation of SAN

Properties of SAN

1. SAN has very good tensile and flexural strength.

2. SAN has good abrasion resistance and impact strength.

3. SAN has high chemical resistance, better resistance to stress cracking and crazing.

4. SAN has good resistance to water, acid, and alkalis.

Applications of SAN

1. SAN is used in the kitchen in mixing bowls, basins, and fitting for refrigerators as it is resistant to oil and fats.

2. SAN is used in making thermally insulated jugs, tableware, cutlery, coffee filters, etc.

3. Due to its toughness, SAN is used in heavy machinery like winding cores, air-conditioners, etc.

4. Due to its pleasing appearance, SAN is used in the bathroom as premium bathroom fittings and cosmetic packaging.