Polyolefins: Types, Properties and Applications

What are Polyolefins?

A polymer that is produced from a simple olefin monomer (also called alkene having general formula CₙH₂ₙ) is called Polyolefin.

For example

(a) Polyethene is a polyolefin produced by polymerization of olefin ethylene

(b) Polypropylene is a polyolefin produced by polymerization of olefin propylene.

The IUPAC nomenclature of polyolefins is poly (alkene). Polyolefins are produced by different common forming techniques like injection molding, blow molding, extrusion, and thermoforming using standard thermoplastic equipment.

Due to low prices and easy processability, polyolefins have a variety of applications in the plastic industry.

Application of Polyolefins

1. Polyolefins are used for making blow-molded components in toys. They are also used to make heat-shrink tubing which protects connections in electronic items.

2. Polyolefins are used in the pharmaceutical and medical industry for HEPA filter certification.

3. Polyolefins sheets have packaging applications of food and other eatable items.

4. Polyolefin waste is used in the manufacturing of different products like pure polymers, naphtha, clean fuels, etc.

Types of Polyolefins

Following are the most common types of polyolefins that we use today:

Polythene or Polyethylene

Polythene is an addition polymer that was first prepared by free radical or high-temperature polymerization of ethene. It is widely used in the plastic industry for the manufacturing of plastic bags, plastic films, bottles, etc.

Following are the two types of polythenes that are widely used:

(a) Low-density polythene (LDP) or Low-density polyethylene (LDPE)

LDPE is a very flexible and tough polyethylene that is manufactured by heating ethylene to 350-570 K under a pressure of 1000-2000 atmospheres in the presence of oxygen or peroxide.

LDPE which is produced has a molecular mass of about 20000 and has a highly branched structure due to hydrogen abstraction.

Preparation of LDPE with the mechanism

LDPE is prepared by free-radical polymerization at high temperatures in which the growing free radicals not only add to the double bond of the monomer but also abstract hydrogen from a chain already formed. This abstraction generates a new free radical center from which a chain can grow.

Properties of LDPE

1. It is a transparent polymer of moderate tensile strength and high toughness.

2. It is chemically inert and slightly flexible.

3. It is a poor conductor of electricity.

4. It has a low heat deflection temperature and melting point as compared to HDPE.

5. It has a high degree of branching which results in a lower degree of crystallinity in the range of 40-55 %.

Applications of LDPE

1. It is widely used as a packaging material in the form of thin plastic films, bags, etc.

2. It is used as an insulator for electrical wires and cables.

3. It is used in the manufacturing of squeeze bottles, toys, and flexible pipes.

(b) High-density polythene (HDP) or High-density polyethylene (HDPE)

HDPE is a thermoplastic polymer that has a high density (0.97 g/cm³) and high melting (403 K) as compared to LDPE. It is prepared by coordination polymerization of ethene and has a wide application in the manufacturing of milk jugs, bleach bottles, pipes, etc.

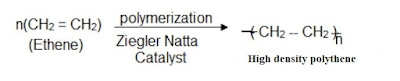

Preparation of HDPE

HDPE is prepared by coordination polymerization of ethene. In this process, ethene (in a hydrocarbon solvent) is heated to 333-343 K under a pressure of 6-7 atmosphere in a presence of a Ziegler-Natta catalyst.

Properties of HDPE

1. It is translucent.

2. It is chemically inert but has greater toughness, hardness, and tensile strength than low-density polythene (LDPE).

3. It has a low degree of branching which results in a higher degree of crystallinity in the range of 70-80 %.

4. It has a high density (0.97 g/cm³) and high melting point (403 K) as compared to LDPE.

Applications of HDPE

1. It is used in the manufacturing of containers (buckets, tubs, etc) housewares, pipes, bottles, and toys.

2. Due to high strength and UV resistance, it is used in the piping system of homes, cities, and towns.

3. It is used in heavy machinery in factories due to its stress crack resistance property.